Igraphite efakwe ubhedu yenziwe ngamasuntswana egraphite kunye nobhedu. Phakathi kwabo, i-graphite yinto ye-carbonaceous, enokuthi ihlulwe ibe yi-graphite yendalo kunye ne-graphite yokwenziwa. Ifom ye-crystal ye-graphite yendalo i-hexagonal sheet, kunye ne-crystallinity ephezulu kunye ne-thermal conductivity ephezulu. Yeyona nto ibalaseleyo ye-thermal conductivity. I-graphite eyenziweyo ilungiselelwe ngokuyininzi i-sintering ephezulu yokushisa kunye nezinye iinkqubo, kwaye ineempawu ze-homogeneity elungileyo kunye namandla aphezulu.

Amasuntswana obhedu adibanisa ubhedu kunye negraphite ngenkqubo ethile yokwenza igraphite yobhedu. Ubukho bamaqhekeza obhedu abukwazi nje ukuphucula i-conductivity ye-graphite, kodwa nokuphucula amandla kunye nobunzima, ngaloo ndlela kuphuculwe iimpawu zayo zomatshini kunye nokuchasana nokugqoka. Ukongezelela, iinqununu zethusi zinokunciphisa ngokufanelekileyo i-resistiveivity yegraphite kunye nokuphucula ukuqhutyelwa kwayo kwe-thermal.

Iifom zemveliso ye-graphite efakwe nge-copper-impregnated, enokuthi ihlulwe ibe yiplate, umbhobho, umgubo kunye nezinye iifom.

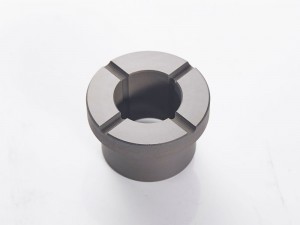

I-Plate yenye yeefom zemveliso eziqhelekileyo. Yenziwe ngegraphite kunye nomgubo wobhedu ngokucinezela ubushushu obuphezulu. Ubukhulu buphakathi kwe-1mm kunye ne-6mm. Ubude nobubanzi bunokwenziwa ngokweemfuno zangempela. Umphezulu wepleyiti ugudileyo kwaye ufana, kwaye unomshini, uqhutywe kwaye ubethelwe ukuhlangabezana neemfuno zezicelo ezahlukeneyo.

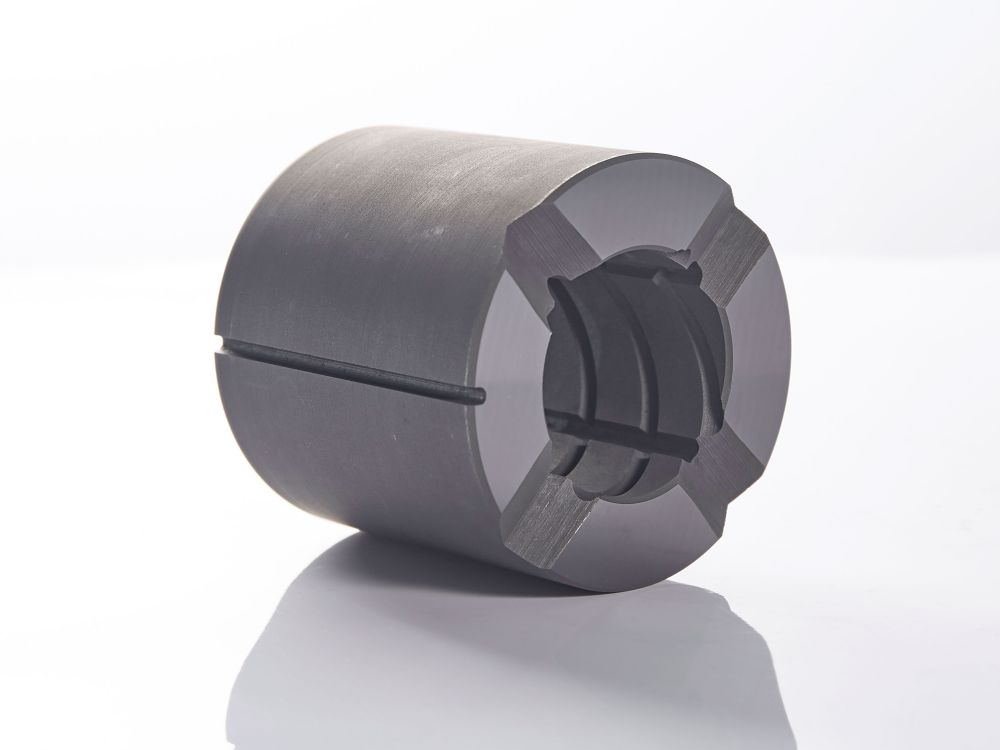

Umbhobho wenziwa nge-extrusion emva kokuxuba igraphite kunye namasuntswana obhedu. Umphezulu wayo wangaphakathi nangaphandle ugudile kwaye ufana. Inokucutshungulwa kunye nemingxuma yangaphakathi kunye neendawo zangaphandle zokuvelisa i-electrodes, i-capacitors, i-high-voltage oil-immersed transformers kunye nezinye izixhobo.

I-powder yenziwe nge-graphite kunye ne-copper particles ngokusebenzisa inkqubo ekhethekileyo yokugaya. Ubungakanani beqhekeza lepowder bunokulungelelaniswa ngokweemfuno zangempela. Inamanqaku amaninzi oqhagamshelwano kunye nokuqhuba kakuhle. Ingasetyenziswa ngokubanzi kwizixhobo zombane, izixhobo zebhetri kunye nezinye iinkalo.

Inkqubo yokwenziwa kwegraphite yobhedu ilula, ibandakanya la manyathelo alandelayo:

1. Izinto zokulungiselela: i-powder yethusi kunye ne-graphite powder iya kuxutywa kwinqanaba elithile, kwaye inani elithile le-lubricant kunye ne-binder liya kudibaniswa.

2. Ukulungiswa komzimba wokubumba: cinezela izinto ezixubileyo kumzimba wokubumba olungele ukuqhutyelwa.

3. Ukomisa kunye nokucubungula: yomisa ukubumba, kwaye emva koko usebenze, njengokujika, ukugaya, ukugaya, njl.

4. I-Sintering: i-sintering amacandelo acutshungulwayo ukwenza i-graphite yobhedu eqinileyo.

Iimpawu eziphambili zegraphite efakwe ngobhedu zezi zilandelayo:

(1) I-conductivity enhle: i-graphite yobhedu efakwe ubhedu iqulethe amaninzi amasuntswana obhedu, okwenza ukuba ukuqhuba kwayo kube kuhle kakhulu.

(2) Iimpawu ezilungileyo zomatshini: ubukho bamasuntswana obhedu buphucula amandla kunye nobunzima begraphite, okwenza kube neempawu ezintle zoomatshini.

(3) Ukumelana nokunxiba kakuhle: ubukho bamasuntswana obhedu bunokuphucula nokumelana nokunxiba kwegraphite.

(4) Uxhathiso olulungileyo lokutya: igraphite ngokwayo inokumelana ne-corrosion elungileyo. Ngokongezwa kweengqungquthela zobhedu, ukuxhathisa kwayo kwe-corrosion kugqwesileyo ngakumbi.

(5) Ukuqhuba kakuhle kwe-thermal: igraphite yinto ebalaseleyo ye-thermal conductivity. Emva kokufaka amaqhekeza obhedu, ukuqhutyelwa kwayo kwe-thermal kungcono nakakhulu.

I-graphite efakwe kwi-Copper ine-conductivity egqwesileyo kunye neempawu zoomatshini, kwaye isetyenziswa ngokubanzi kwizinto zebhetri, ulawulo lwe-thermal, izixhobo zombane, ukuveliswa koomatshini kunye nezinye iindawo.

Kwintsimi yezixhobo zebhetri, i-graphite efakwe ngobhedu isetyenziswe ngokubanzi ekulungiseleleni iipleyiti ze-electrode zebhetri ukuphucula ukusebenza kweebhetri ngenxa ye-conductivity egqwesileyo kunye neempawu zomatshini.

Kwintsimi yolawulo lwe-thermal, i-graphite efakwe nge-copper-impregnated ingenziwa kwi-heat conducting fins yokutshatyalaliswa kobushushu bezixhobo ezahlukeneyo ze-elektroniki. Ngenxa ye-thermal conductivity egqwesileyo, inokukhupha ngokukhawuleza ukushisa, ngaloo ndlela iqinisekisa ukusebenza okuzinzile kwexesha elide lezixhobo.

Kwintsimi yezixhobo zombane, i-graphite ene-copper-impregnated ingasetyenziselwa ukuvelisa i-capacitors, i-high-voltage oil-immersed transformers kunye nezinye izixhobo. Ngenxa ye-conductivity yayo efanelekileyo, inokudlulisa ngokufanelekileyo izibonakaliso zombane kunye namandla, ngoko inokuhlangabezana neemfuno zezixhobo zombane ezahlukeneyo.

Kwintsimi yokwenziwa koomatshini, igraphite efakwe ngobhedu inokwenziwa kwiimilo ezahlukeneyo zeepleyiti, imibhobho, iipowders, njl., ukuhlangabezana neemfuno ezahlukeneyo zokwenziwa koomatshini. Kwangaxeshanye, ukuxhathisa kwayo ukunxitywa kunye nokumelana nokugqwala kuyenza ibe yeyona nto ifanelekileyo yokwenziwa koomatshini.